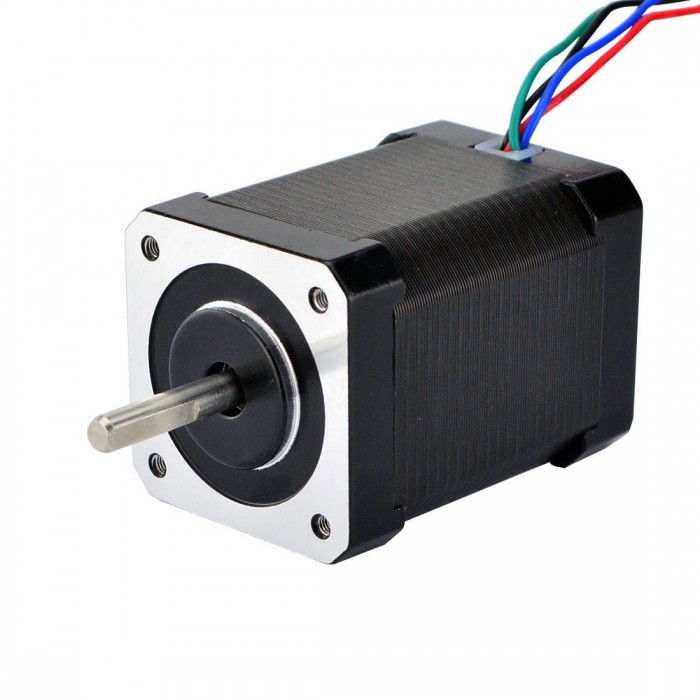

Stepper motors that are traditional rotary motors couple to mechanical rotary-to-linear motion devices (often in the form of a threaded shaft that mates with traversing nut or carriage) to produce linear motion. In this actuator setup, the motor output shaft usually couples to the screw to turn it … and advance the nut (or carriage) and attached load. These are usually small designs that go into consumer products or small-stroke applications in industrial machines.

17HS24-2104S

Summary of linear stepper motors

Engineers most commonly use these linear actuators in larger installations; on axes that move heavier loads; and in high-end medical or material-handling applications such as pick-and-place machinery that require extremely high precision. Like rotary equivalents, linear stepper motors either use a variable reluctance (just described) or a hybrid mode of operation. A hybrid linear-stepper platen is like that of a variable-reluctance linear stepper. In contrast, the forcer has multiple permanent magnets, magnetic U-shaped cores (with coils around them) and a steel yoke.

Summary of rotary-stepper-driven axes

When engineers use rotary-stepper-driven axes instead of linear stepper motors, they face a different set of design considerations. For starters, the engineer must pick the leadscrew’s lead and pitch. Lead defines the distance a screw thread advances in one revolution. Pitch is the distance between adjacent threads. A small lead with more threads per inch outputs higher force and resolution; large leads (or fewer threads) output lower force but higher speed.

One final note on rotary-stepper-driven axes: Because these linear actuator stepper motor incorporate mechanical components, they exhibit wear and life limitations. That said, when engineers properly size for the load and create a forgiving operating environment (with low humidity, protection from harsh chemicals and dirt, and controlled temperature) rotary-stepper-driven exhibit long life—to millions of cycles.

http://www.fxstat.com/en/user/profile/zhidaowozzou4-182008/blog/34451057-Stepper-motor-for-a-mechatronic-application-is-so-important

https://bestnewkinder.blogspot.com/2020/02/what-is-pulse-needed-to-move-stepper.html

没有评论:

发表评论