Stepper motors generally are not available in frame sizes larger than NEMA 34, with most applications falling in the NEMA 17 or NEMA 23 motor sizes. As a result, it is unusual to find stepper motors capable of producing more than 1000 to 2000 ounce inches of torque.

Adding an encoder will enable the system to accurately track movement, but it will not be able to overcome the basic physics of the motor. For applications requiring improved positioning accuracy and resolution, servo motors provide a better solution.

Servo Motors

Like stepper motors, servo motors have many implementations. Let’s consider the most common design, which incorporates a rotor with permanent magnets and a stationary stator with the windings. Here too, the current creates a magnetic field distribution that acts on the rotor to develop torque. Servo motors have significantly lower pole counts than stepper motors, however. As a result, they must be run closed-loop.

Final ThoughtsServo motors offer an undeniable performance advantage. In terms of repeatability, however, stepper motors can be quite competitive. This point brings up a common misconception about stepper motors, which is the myth of lost motion. As we discussed previously, the mass-spring nature of a stepper motor may result in a few lost steps. Because the drive is commanding the stepper to move to an angular location, lost steps are not carried over from rotation to rotation, however. Rotation to rotation, stepper motors are highly repeatable. Look for a more detailed discussion of this topic in a future blog post.

When your application is forgiving but your budget is not, consider a stepper motor. If performance is the most important aspect, a servo motor will do the job but be prepared to pay more.

Design Tips for Using Step Motors

Some Basic Knowledge among Nema17, NEMA 23 and NEMA 24 motor

2020年2月25日星期二

2020年2月18日星期二

The Basic Knowledge and Application of Stepper Motor

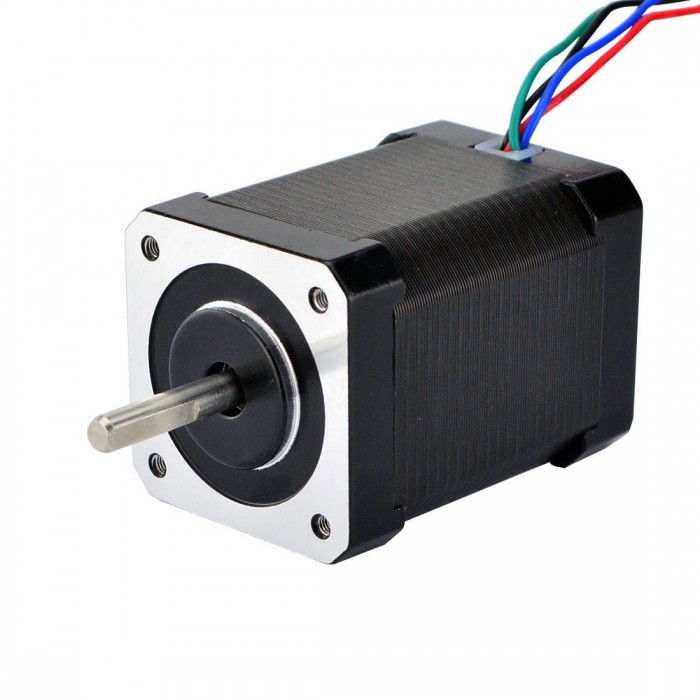

What is a stepper motor? Stepper motor is an actuator transforming electric pulse into angular displacement. Popularly, when receiving a pulse signal, the stepper motor will rotate a fixed angle (namely"stepping angle") according to the direction set for the stepper motor. The angular displacement volume can be controlled by controlling the pulse number to achieve the purpose of positioning accurately. In the meantime, the rotational velocity and acceleration of motor can be controlled by controlling the pulse frequency to achieve the purpose of speed control.

The stepper motor is an electromagnetic device that converts digital pulses into mechanical shaft rotation. Advantages of step motors are low cost, high reliability, high torque at low speeds and a simple, rugged construction that operates in almost any environment.

The most widely used motors in motion controls are stepper motors. Stepper motors are relatively inexpensive compared to brushless dc motors. They are able to be very accurately controlled for the most precise positioning applications without any feedback devices like encoders or hall sensors. Stepper motors can be classified by different ways of wiring (unipolar or bipolar), various step angles (1.8 degree, 0.9 degree or micro stepping) and the numerous NEMA frame sizes. NEMA frame sizes refer to the motor mounting pattern.

It was brought up by National Electrical Manufacturers Association to indicate the physical characteristics of the stepper motor. It has nothing to do with the motor’s electrical characteristics such as horsepower or voltage. For example, a NEMA 17 stepper motor has a 1.7 inch square flange with 4 mounting holes, one at each corner of the square. Likewise, a NEMA 23 stepper motor has a 2.3 inch square mounting flange with an individual hole at each corner. Currently, the most commonly used stepper motors are NEMA 17 NEMA 23 and NEMA 34. But in some specific applications, NEMA 8 NEMA 11 NEMA 14 and NEMA 42 stepper motors are also used.

Stepper motor is divided into three types: permanent magnet stepper motor (PM), variable reluctance stepper motor (VR) and hybrid stepper motor (HB).

The operation of this motor works on the principle that unlike poles attract each other and like poles repel each other. When the stator windings are excited with a DC supply, it produces magnetic flux and establishes the North and South poles.

Choosing a Stepper Motor and the controller

Choose the right stepper motor for your application

The stepper motor is an electromagnetic device that converts digital pulses into mechanical shaft rotation. Advantages of step motors are low cost, high reliability, high torque at low speeds and a simple, rugged construction that operates in almost any environment.

The most widely used motors in motion controls are stepper motors. Stepper motors are relatively inexpensive compared to brushless dc motors. They are able to be very accurately controlled for the most precise positioning applications without any feedback devices like encoders or hall sensors. Stepper motors can be classified by different ways of wiring (unipolar or bipolar), various step angles (1.8 degree, 0.9 degree or micro stepping) and the numerous NEMA frame sizes. NEMA frame sizes refer to the motor mounting pattern.

It was brought up by National Electrical Manufacturers Association to indicate the physical characteristics of the stepper motor. It has nothing to do with the motor’s electrical characteristics such as horsepower or voltage. For example, a NEMA 17 stepper motor has a 1.7 inch square flange with 4 mounting holes, one at each corner of the square. Likewise, a NEMA 23 stepper motor has a 2.3 inch square mounting flange with an individual hole at each corner. Currently, the most commonly used stepper motors are NEMA 17 NEMA 23 and NEMA 34. But in some specific applications, NEMA 8 NEMA 11 NEMA 14 and NEMA 42 stepper motors are also used.

Stepper motor is divided into three types: permanent magnet stepper motor (PM), variable reluctance stepper motor (VR) and hybrid stepper motor (HB).

The operation of this motor works on the principle that unlike poles attract each other and like poles repel each other. When the stator windings are excited with a DC supply, it produces magnetic flux and establishes the North and South poles.

Choosing a Stepper Motor and the controller

Choose the right stepper motor for your application

2020年2月15日星期六

Do I need an encoder to run a step motor, right?

Step motors offer the automation industry a cost-effective and simple method to digitally control motion in a wide range of applications — including packaging equipment, 3D printers, material handling and sorting lines, benchtop CNC machines, and more. They serve as critical components of many rotary and linear positioning axes.

No, an encoder is not required to run a step motor in open-loop control. Step motors are the only type of brushless DC motor that accurately and repeatedly position a load using open-loop control. Other motors need some type of position feedback. Open-loop control works well when:

Motion tasks are the same over time.

The load doesn’t change.

The required speeds are relatively low.

Failure to complete the motion task does not result in critical or dangerous machine failure.

If the application doesn’t meet the stated criteria, consider introducing feedback into the system to permit some level of closed-loop control. Adding an encoder to a step motor system offers benefits ranging from basic functions that are essentially open-loop control but with subtle, effective improvements, to fully closed-loop stepper motor control where the step motor operates as part of a servo control system. Contact your step motor and drive supplier for information on the range of feedback and closed-loop control options they offer.

NEMA frame size used for stepper motors and brushless DC motors

Some Knowledge of Shaft Style, Motor Size and Gearing

No, an encoder is not required to run a step motor in open-loop control. Step motors are the only type of brushless DC motor that accurately and repeatedly position a load using open-loop control. Other motors need some type of position feedback. Open-loop control works well when:

Motion tasks are the same over time.

The load doesn’t change.

The required speeds are relatively low.

Failure to complete the motion task does not result in critical or dangerous machine failure.

If the application doesn’t meet the stated criteria, consider introducing feedback into the system to permit some level of closed-loop control. Adding an encoder to a step motor system offers benefits ranging from basic functions that are essentially open-loop control but with subtle, effective improvements, to fully closed-loop stepper motor control where the step motor operates as part of a servo control system. Contact your step motor and drive supplier for information on the range of feedback and closed-loop control options they offer.

NEMA frame size used for stepper motors and brushless DC motors

Some Knowledge of Shaft Style, Motor Size and Gearing

2020年2月13日星期四

Stepper motors go into linear actuators in two different ways

Stepper motors go into linear actuators in two different ways

Stepper motors that are traditional rotary motors couple to mechanical rotary-to-linear motion devices (often in the form of a threaded shaft that mates with traversing nut or carriage) to produce linear motion. In this actuator setup, the motor output shaft usually couples to the screw to turn it … and advance the nut (or carriage) and attached load. These are usually small designs that go into consumer products or small-stroke applications in industrial machines.

17HS24-2104S

Summary of linear stepper motors

Engineers most commonly use these linear actuators in larger installations; on axes that move heavier loads; and in high-end medical or material-handling applications such as pick-and-place machinery that require extremely high precision. Like rotary equivalents, linear stepper motors either use a variable reluctance (just described) or a hybrid mode of operation. A hybrid linear-stepper platen is like that of a variable-reluctance linear stepper. In contrast, the forcer has multiple permanent magnets, magnetic U-shaped cores (with coils around them) and a steel yoke.

Summary of rotary-stepper-driven axes

When engineers use rotary-stepper-driven axes instead of linear stepper motors, they face a different set of design considerations. For starters, the engineer must pick the leadscrew’s lead and pitch. Lead defines the distance a screw thread advances in one revolution. Pitch is the distance between adjacent threads. A small lead with more threads per inch outputs higher force and resolution; large leads (or fewer threads) output lower force but higher speed.

One final note on rotary-stepper-driven axes: Because these linear actuator stepper motor incorporate mechanical components, they exhibit wear and life limitations. That said, when engineers properly size for the load and create a forgiving operating environment (with low humidity, protection from harsh chemicals and dirt, and controlled temperature) rotary-stepper-driven exhibit long life—to millions of cycles.

http://www.fxstat.com/en/user/profile/zhidaowozzou4-182008/blog/34451057-Stepper-motor-for-a-mechatronic-application-is-so-important

https://bestnewkinder.blogspot.com/2020/02/what-is-pulse-needed-to-move-stepper.html

Stepper motors that are traditional rotary motors couple to mechanical rotary-to-linear motion devices (often in the form of a threaded shaft that mates with traversing nut or carriage) to produce linear motion. In this actuator setup, the motor output shaft usually couples to the screw to turn it … and advance the nut (or carriage) and attached load. These are usually small designs that go into consumer products or small-stroke applications in industrial machines.

17HS24-2104S

Summary of linear stepper motors

Engineers most commonly use these linear actuators in larger installations; on axes that move heavier loads; and in high-end medical or material-handling applications such as pick-and-place machinery that require extremely high precision. Like rotary equivalents, linear stepper motors either use a variable reluctance (just described) or a hybrid mode of operation. A hybrid linear-stepper platen is like that of a variable-reluctance linear stepper. In contrast, the forcer has multiple permanent magnets, magnetic U-shaped cores (with coils around them) and a steel yoke.

Summary of rotary-stepper-driven axes

When engineers use rotary-stepper-driven axes instead of linear stepper motors, they face a different set of design considerations. For starters, the engineer must pick the leadscrew’s lead and pitch. Lead defines the distance a screw thread advances in one revolution. Pitch is the distance between adjacent threads. A small lead with more threads per inch outputs higher force and resolution; large leads (or fewer threads) output lower force but higher speed.

One final note on rotary-stepper-driven axes: Because these linear actuator stepper motor incorporate mechanical components, they exhibit wear and life limitations. That said, when engineers properly size for the load and create a forgiving operating environment (with low humidity, protection from harsh chemicals and dirt, and controlled temperature) rotary-stepper-driven exhibit long life—to millions of cycles.

http://www.fxstat.com/en/user/profile/zhidaowozzou4-182008/blog/34451057-Stepper-motor-for-a-mechatronic-application-is-so-important

https://bestnewkinder.blogspot.com/2020/02/what-is-pulse-needed-to-move-stepper.html

2020年2月11日星期二

3 methods to reduce high temperature heat

Step motors for sale are widely used motion-control devices because of their simple setup and accurate positioning with an open-loop configuration. But problems associated with heat generation can arise. That’s because the drive that powers an open-loop step motor doesn’t use feedback to control the amount of current provided to that motor. Instead, the drive provides full current at all times … regardless of torque demand on the motor. So the motor consumes power at excessive rates …. wasting energy and generating avoidable amounts of heat.

First — Reduce the idle (holding) current for the motor

Many motion control applications need the most torque when the motor accelerates and decelerates to meet its mark. But when the motor idles, or holds position, it requires much less torque. These instances are a good time to reduce motor current.

Second — Reduce running current

Many design engineers err on the side of caution when selecting a step motor — often choosing a motor with more than enough torque (rather than just enough) for the application at hand. In these scenarios, it may be possible to reduce the motor’s running current with some trial-and-error testing. Basically, this requires reducing running current by a small amount and monitoring the motion output. If this trial run proves successful, reduce running current again and retest motor performance.

Third — Switch to a closed-loop step motor system

The most dramatic reduction in heat generation occurs when replacing an open-loop step motor system with a closed-loop step motor system. Step motors are operable within a servo control loop when outfitted with a high-resolution encoder and powered by a suitable closed-loop drive. This relatively new system configuration necessitates that the engineer replaces the application’s motor and drive. But the magnitude of temperature reduction is usually worth it.

See more:

https://www.behance.net/tamaratrelevska12/

https://www.tripoto.com/trip/faq-of-linear-stepping-motor-basics-you-shold-know-5e427217da5ef

订阅:

博文 (Atom)